Efficient 3D Design System

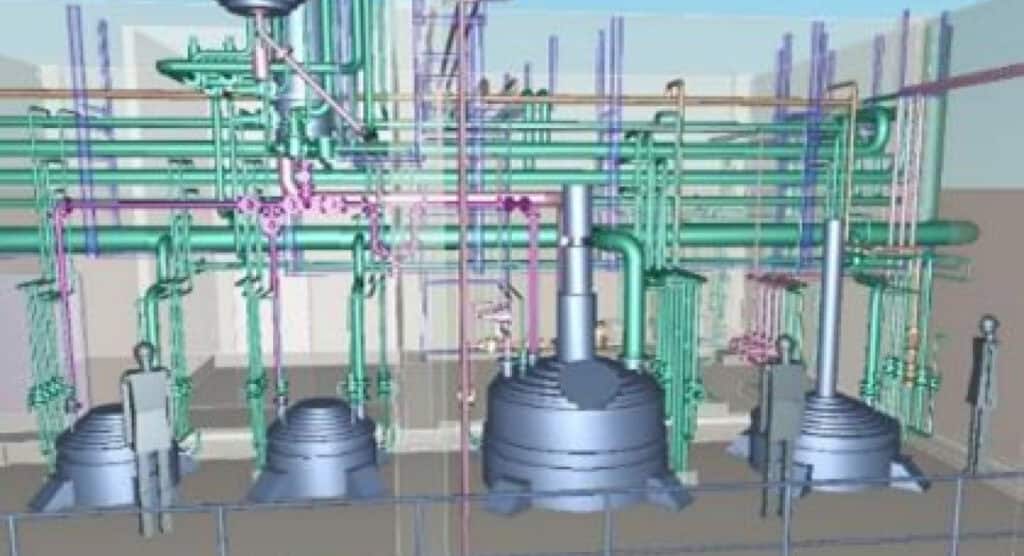

One of the technologies we currently utilize is 3D design software. This system has proven to be the backbone of designing complex mechanical, electrical, and plumbing (MEP) systems. With 3D technology, our team can visualize projects in more detailed and accurate three-dimensional models compared to conventional methods. The main advantage of using this software lies in the efficiency it offers in the design process. Every element of the MEP system can be designed, tested, and refined digitally before physical construction begins. This not only saves time but also minimizes costly design errors that could be detected later in the field.

Visual Presentation for Project Owners

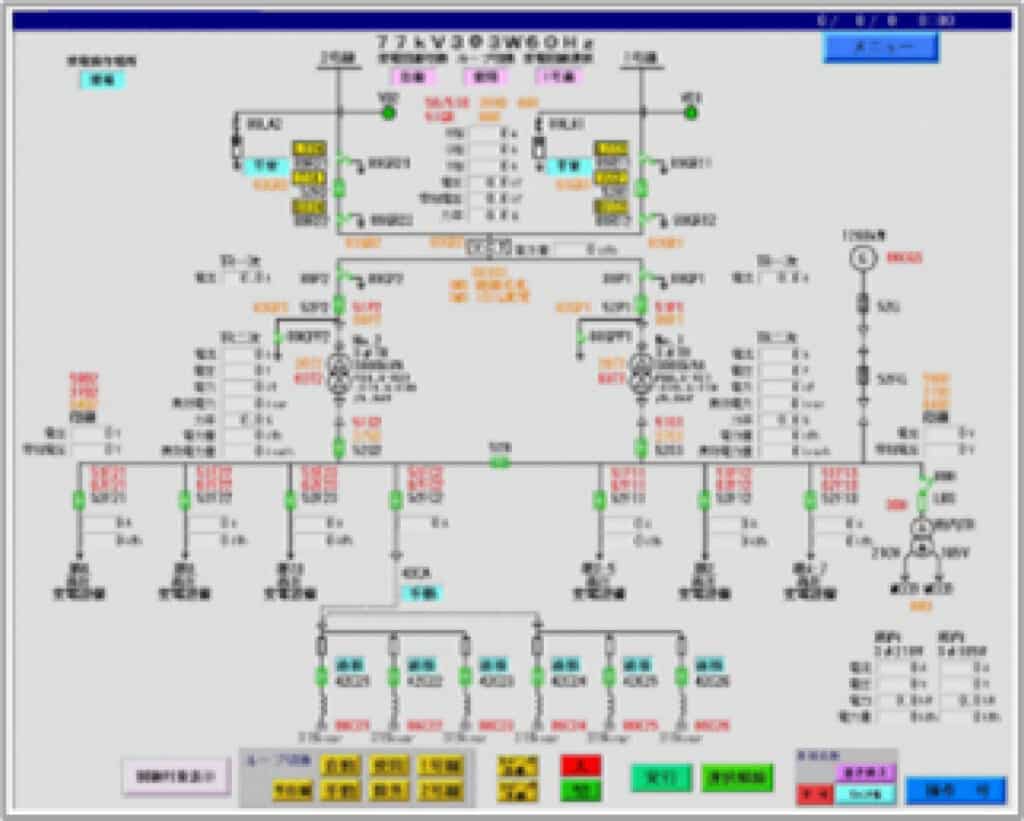

In addition to improving internal efficiency, this 3D technology also makes it easier to present designs to project owners. In the construction industry, the ability to communicate design vision to stakeholders is crucial. With interactive 3D models, we can present objects visually in a way that is more easily understood by project owners. They no longer need to rely on imagination or interpretation of two-dimensional images but can see realistic visual representations of their projects. This allows project owners to provide more specific feedback and ensures that the proposed design aligns with their vision.

Automatic and Accurate Material Calculation

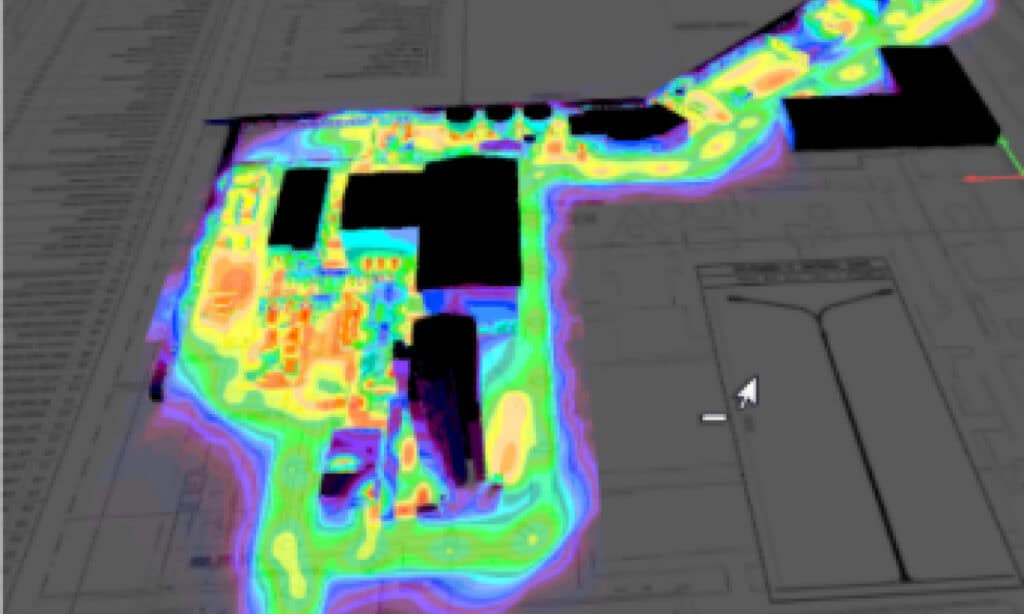

Another equally important technology is the automated system we use to calculate material needs in detail. In construction projects, inaccurate material estimates can lead to waste or even project delays. By using this automated system, our company ensures that every detail of material requirements, from pipes to electrical cables, is calculated accurately. This not only reduces the risk of errors but also ensures that resources are used efficiently and sustainably. Accurate material planning helps reduce waste and keeps the project budget under control.

Coordination Challenges and Integrated Design

However, the greatest challenge in the MEP industry is not just about efficiency but also about effective integration between mechanical, electrical, and plumbing components. These three systems must work together seamlessly for optimal building performance. Design conflicts between systems can lead to additional costs and suboptimal performance. Therefore, technology that enables cross-disciplinary coordination is crucial. With interactive and comprehensive 3D models, our team can identify potential design conflicts early on and resolve them before construction begins.

In all of this, our company demonstrates a commitment not only to keeping up with technological advancements but also to using them creatively to solve challenges. Thus, our company is not just a player in the industry but a leader, chosen and recognized for its creativity in facing challenges. In this context, technology is not merely a tool but a catalyst that drives innovation and efficiency at every step of the project.